Used machines for sale

Aluminum can tamper Aluminum can tamper

Main brands:

Angelus, Continental, Dixie Canner, Goetz, Holstein Kappert, KHS, Krones Taxomatic, krones Ultramatic, Metalgraf, Mitri Sleap, Paramix Mojonnier, Zegla

|

| Aluminum can tamper |

A rotary or linear automatic can crimper is a machine used in the packaging industry to fix or crimp the metal lid on metal cans. This process is crucial to guarantee the hermetic sealing of cans, preserving the quality and integrity of the products stored inside. Here is a more detailed explanation of its function and operation:

1. Heremetic Sealing:

The can seamer's main function is to create an airtight seal between the lid and the can body. This sealing is vital to protect the contents of the can against external factors, such as air, humidity and contaminants, which could compromise the quality and durability of the stored products.

2. Operation:

The general rotary can crimping process involves a few key steps:

Supply of Cans and Lids:

Empty cans and metal lids are fed into the machine automatically. This feeding can be done in-line or in separate stations, depending on the machine design.

Positioning of Cans and Lids:

Cans and lids are precisely positioned to ensure proper alignment during the crimping process.

Reseating:

The machine rotates the cans and lids while applying pressure to crimp the lid into the can body. This process is carried out precisely to ensure an airtight seal.

Inspection and Quality Control:

After crimping, cans can pass through automated inspection systems to ensure proper sealing. This may include visual verification, sensor inspection, or other quality control technologies.

Exit of Sealed Cans:

Successfully sealed cans are then directed to the next step in the packaging process, such as labeling, packaging or other final processes.

3. Variations in Technology:

Rotary can seamers can vary in terms of capacity, speed and technology. Some machines are designed to operate at high speeds to suit large-scale production lines, while others may be better suited for smaller-scale production.

The use of rotary can seamers is common in industries that involve filling food, beverages, chemicals and other products into metal containers. These machines play a crucial role in ensuring the quality and safety of packaged products. |

|

|

|

|

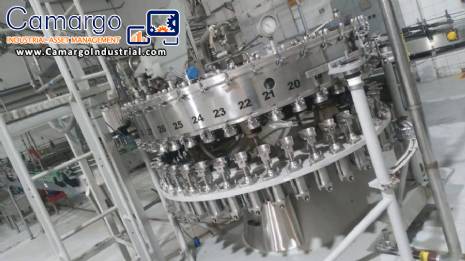

Depaselining line, transportation, washing rinser, filling machine, can seamers.

Depalitiser for 30,000 cans per hour, depending on size.

Online conveyor.

Mesaninos walkway.

Rotary filling machine for carbonated drinks.

Manufacturer br... |

|

|

|

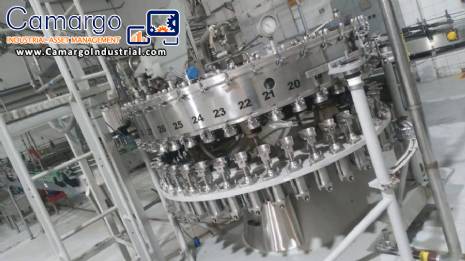

Brand: Metalgraf

Components: Siemens

4-head seamer for metal cans.

Manufacturer/brand: Metalgraf.

Year: 1994.

With manual.

Approximate capacity: 90 cans per minute.

With panel.

Components: Siemens frequency inverter.

WEG motor.... |

|

|

|

Brand: Brapenta, Masipack, Metalgraf, Neife, Strapet Embalagens

Components: Siemens, WEG

Can filling system.

Line for filling powdered products in cans, jars and bottles.

The line worked with 400 g cans and a taller 510 g can.

Depending on the density of the product, it can fill up to 600 grams.

- Dosing filling machine for j... |

|

|

|

Seamer for cans.

Approximate measurements:

Height 1600 mm x Width 900 mm x Length 900 mm.... |

|

|

|

Brand: Toledo

Can filling line for powder products.

It was used to fill cans of powdered milk.

Approximate capacity: from 80 to 100 cans / minute.

For cans with a diameter of 198 mm.

For more information, get in touch.

Line composed of:

- Depalat... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Photos and images sent by email will be considered as ad authorization on our websites and marketing.

Camargo Industrial has no responsability for the data delivered by the advertiser, (Operation, technical, maintenance, warranties, technical delivery) and registration of the same data, exempting Camargo Industrial responsibilities on the veracity of the information described, civil and criminally.

The advertiser declares that the equipment is their property, settled without alienation, pending fiscal or judicial attachment.

Standard Work Safety of Machines and Equipment (NR12): 12.1.1. Camargo Industrial does not participate in the use phase construction, transport, assembly, installation, adjustment, operation, cleaning, maintenance, inspection, decommissioning and dismantling of machinery or equipment, any such liability of the seller attributes and / or buyer, relieving - any responsibility Camargo Industrial.

|

|

| |

|