Used machines for sale

Can filling machines Can filling machines

Main brands:

Angelus, CarbonaTech, Holstein Kappert, Hosten, KHS, Krones Taxomatic, krones Ultramatic, Masipack, Mitri Sleap, Paramix Mojonnier, Vinox, Zegla

|

| Can filling machines |

An automatic can filler is an industrial machine designed to fill cans with liquid products, such as soft drinks, beers, juices, among others. These machines are common in the beverage and food industries to automate the filling process, making it more efficient and precise. Here is how an automatic can filler generally works and what it is for:

Can feeding: Empty cans are fed into the machine via a conveyor or conveyor system. They can be loaded on pallets or directly from stock.

Rinsing: Before being filled, cans may go through a rinsing process to remove any dirt or residue that may be present inside.

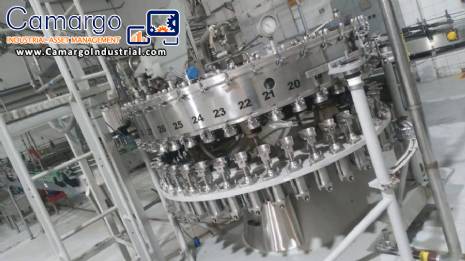

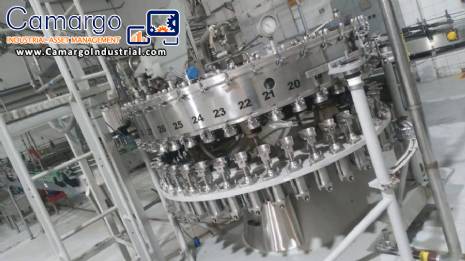

Filling: The cans are positioned under the filling valves. Liquids are pumped into the cans in a precise and controlled manner. This can be done using different methods such as gravity filling, vacuum filling, or pressure filling.

Sealing: After filling, cans are hermetically sealed to maintain product quality and prevent contamination.

Date and coding: Automatic filling machines often also have coding systems to print information such as expiration date, production batch and barcode on the cans.

Quality inspection: Filled and sealed cans are often subjected to automated inspections to ensure product quality, such as checking the fill level, seal integrity and presence of dirt.

Labeling (optional): Some automatic filling machines may also include a labeling station that applies labels to cans, displaying product and brand information.

Final packaging: After the filling process, cans can be sent for additional processes, such as packaging in boxes or pallets, depending on product and customer requirements.

Automatic can fillers offer a series of advantages, such as increased productivity, reduced waste, greater filling precision and improved product hygiene and safety. They are essential for the food and beverage industry, where large-scale production is necessary to meet market demand. |

|

|

|

|

Depaselining line, transportation, washing rinser, filling machine, can seamers.

Depalitiser for 30,000 cans per hour, depending on size.

Online conveyor.

Mesaninos walkway.

Rotary filling machine for carbonated drinks.

Manufacturer br... |

|

|

|

Brand: Brapenta, Masipack, Metalgraf, Neife, Strapet Embalagens

Components: Siemens, WEG

Can filling system.

Line for filling powdered products in cans, jars and bottles.

The line worked with 400 g cans and a taller 510 g can.

Depending on the density of the product, it can fill up to 600 grams.

- Dosing filling machine for j... |

|

|

|

Brand: Toledo

Can filling line for powder products.

It was used to fill cans of powdered milk.

Approximate capacity: from 80 to 100 cans / minute.

For cans with a diameter of 198 mm.

For more information, get in touch.

Line composed of:

- Depalat... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Photos and images sent by email will be considered as ad authorization on our websites and marketing.

Camargo Industrial has no responsability for the data delivered by the advertiser, (Operation, technical, maintenance, warranties, technical delivery) and registration of the same data, exempting Camargo Industrial responsibilities on the veracity of the information described, civil and criminally.

The advertiser declares that the equipment is their property, settled without alienation, pending fiscal or judicial attachment.

Standard Work Safety of Machines and Equipment (NR12): 12.1.1. Camargo Industrial does not participate in the use phase construction, transport, assembly, installation, adjustment, operation, cleaning, maintenance, inspection, decommissioning and dismantling of machinery or equipment, any such liability of the seller attributes and / or buyer, relieving - any responsibility Camargo Industrial.

|

|

| |

|