Used machines for sale

Rinser bottle washers Rinser bottle washers

Main brands:

Alcoa, Angelus, Aplimáquinas, Arbras, Brabeer, Envasare, Holstein Kappert, Imarvil, IMSB, KHS, Montex, Omega Lavana, Rodopac, Zegla, Ziemann Liess

|

| Rinser bottle washers |

A rinser for bottles and jars is equipment used in the packaging industry to clean and rinse bottles or jars before filling them with products, such as beverages, food, chemical or pharmaceutical products. The main function of the rinser is to ensure that packaging is clean and free of residues before filling, contributing to the quality and safety of packaged products. Here are some details about the function and basic functioning of a rinser:

1. Rinser Function:

The main function of a bottle and jar rinser is to remove dirt, particles, dust, or any other residue that may be present on the packaging. This is essential to guarantee the integrity of the final product, prevent contamination and maintain hygiene standards on the filling line.

2. Main Components:

Bottle and jar rinsers can vary in design, but generally have the following main components:

Conveyor Belt: Moves the bottles or jars throughout the process.

Rinsing Stations: Where rinsing is carried out, often using nozzles or injectors of water or other cleaning liquid.

Control System: To operate and control the rinsing process.

3. Basic Operation:

The operating process of a rinser for bottles and jars generally follows the basic steps below:

Packaging Feeding: Empty bottles or jars are fed onto the rinser conveyor belt.

Positioning at Rinsing Stations: As packages advance along the conveyor belt, they are positioned at rinsing stations.

Rinsing: At rinsing stations, nozzles or injectors release water or another cleaning solution to rinse bottles or jars.

Drainage and Exit: After rinsing, the packages pass through a drainage area to remove excess liquid. Afterwards, the clean packaging is sent to the next stage of the process, such as filling the product.

4. Features and Advantages:

Efficient Cleaning: The rinser performs efficient cleaning of packaging, removing particles and dirt.

Versatility: Can be used with different types of packaging, such as glass bottles, plastic or jars.

Automatic Control: Many rinsers have automatic control systems to optimize the process.

Improvement in Product Quality: Contributes to the quality and safety of the final product, avoiding contamination.

The use of a rinser for bottles and jars is a common practice on production lines, especially in industries where hygiene and product quality are priorities. |

|

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Brabeer

Stainless steel filling machine with 2 nozzles for beer bottles.

Includes the rinsing, filling and corking process for liquids.

Manufacturer: Brabeer.

Approximate capacity: 200 bottles per hour.*

* depending on the bottle, product, etc.

... |

|

|

|

Brand: Imarvil

Stainless steel washer bottles, use to sterilize the product packing container to be filled.

the liquid used to wash is alcohol.

Brand: Imarvil... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

Brand: Aplimáquinas

Linear filling machine with 14 nozzles with rinser and screw capper for juices, drinks, water.

Manufacturer | brand: Aplimáquinas.

Line composed of:

- Bottle washer rinser with 5 positions.

Comes with a kit for 5 liters.

- Rotary screw... |

|

|

|

Brand: Zegla

Automatic rinser for bottles.

Manufacturer/brand: Zegla.

Year: 1996.... |

|

|

|

Brand: Zegla

Balloon-type rinser washer for bottles.

Manufacturer/brand: Zegla.

Year: 2000.

For 500 ml, 1500 ml and 2000 ml bottles.... |

|

|

|

Glass bottle rinser washer.

... |

|

|

|

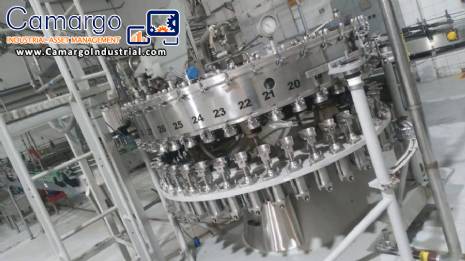

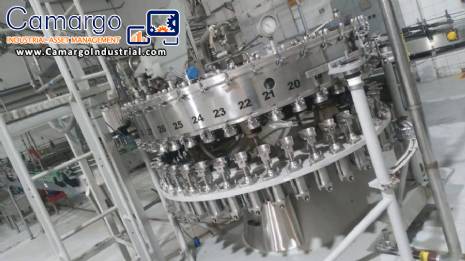

Brand: KHS, Mojonnier, Sabroe, Schulz, Ziemann Liess

Complete line plant for the production of beer and soft drinks.

Line composed of:

Bottle washer.

Manufacturer: Ziemann-Liess / KHS.

With 32 positions.

Year: 1994.

With tank system.

Linear rinser for bottles.

Nominal production... |

|

|

|

Rinser Twister Type 6.85 Meters in length

Composed by dildo, bike pump 1 HP and 1 HP reducer... |

|

|

|

Brand: IMSB, Rodopac

Components: Siemens

Stainless steel monobloc/tribloc filling machine.

Brand: IMSB.

Model: ERSB 1414/4.

Manufacturing Standard: MS.

Electrical Characteristics: 380 V.

Weight: 3.200 KG.

With 14 filling nozzles.

With 4 arms for threading caps.

With ... |

|

|

|

Brand: Envasare

Automatic rinser for bottles.

Manufacturer/brand: Envasare Máquinas.

Model: ENV-RNS - 12P.... |

|

|

|

Brand: KHS, Mojonnier, Posimec, Zegla

Complete line for the manufacture of carbonated beverages (with gas), including soft drinks, energy drinks, juices, alcoholic beverages.

Complete syrup with stainless steel tanks.

Carbon dioxide storage and pumping system for 8,000 kg.

Water... |

|

|

|

Brand: Arbras

Rotary filling machine with 16 nozzles.

With bottle washer rinser.

Brand: Arbras.... |

|

|

|

Brand: Zegla

Filler/Filler with 30 nozzles.

With threader and rinser.

Brand: Zegla.

Model: RZ30.

Year: 2000.

Approximate productivity: 4000 bottles/hour.

Isobaric filling machine for carbonates.... |

|

|

|

Brand: Montex

Bottle washer.

Brand: Montex.

Capacity: 11,000 bottles per hour.

Voltage: 380 v.

Dimensions: 7000 mm x 2100 mm x 1500 mm.

Approximate weight: 300 kg.... |

|

|

|

Brand: Omega Lavana

Large washer for bottles.

Brand: Omega Lavana.

Model: DM 22.

Type: 34/125.

Height: 4.2 m.... |

|

|

|

Brand: Angelus, Grown Simplimatic, Pakmatic, Solbern

Complete line for can depalatization, rinser, filling, can rewriter, conveyor, chiller tunnel, baler, palletizer and strech wrapper.

More information get in touch.

Production: 42,000 u / h.

Depalletizer.

Brand: Grown Simplimatic.

Washe... |

|

|

|

Brand: Arbras

Rotary filling machine rinser and capping bottle machine

Complete line for packaging.

Brand: Arbras.

With system of feeding bottles and lids.

Stainless steel.

Machine in acrinilo.... |

|

|

|

Brand: Macmundi, Projepack, Vinox

VINOX filler/Capper monoblock.

Vxetgr model 12/4.

For non-carbonated mineral water PET 510 ml and 1.5 litres.

3000 unit production per hour reference 510 ml.

Vacuum and tunnel Projepack conjugate.

SLT model-400/RE (electric tunnel) to pac... |

|

|

|

Brand: Holstein Kappert

Industrial Washing Machine.

Brand name: Holstein Kappert.

No. 301.

Type: 23/90.

Manufactured: 1976.... |

|

|

|

Brand: Alcoa, Ata, Holstein Kappert, Rotix

Line for filling bottles of 180 ml to 1000 ml, and the washing machine can wash up to liter of brandy

01 washing machine bottles Holstein Kappert-P/16000 bottles/hour

1 Filler Kappert 60/10 Holstein P/9600 bottles/hour (Corker)

Rotix Labeller p... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Photos and images sent by email will be considered as ad authorization on our websites and marketing.

Camargo Industrial has no responsability for the data delivered by the advertiser, (Operation, technical, maintenance, warranties, technical delivery) and registration of the same data, exempting Camargo Industrial responsibilities on the veracity of the information described, civil and criminally.

The advertiser declares that the equipment is their property, settled without alienation, pending fiscal or judicial attachment.

Standard Work Safety of Machines and Equipment (NR12): 12.1.1. Camargo Industrial does not participate in the use phase construction, transport, assembly, installation, adjustment, operation, cleaning, maintenance, inspection, decommissioning and dismantling of machinery or equipment, any such liability of the seller attributes and / or buyer, relieving - any responsibility Camargo Industrial.

|

|

| |

|