Used machines for sale

Vibrating screen Vibrating screen

Main brands:

Águia Inox, BTZ, Consolid, Mavi, Mineraltec, MVL

|

| Vibrating screen |

A vibrating sieve, also known as a circular vibrating sieve or linear vibrating sieve, is a piece of equipment used in industry to separate solid particles of different sizes. It plays a crucial role in classification and sieving processes, being applied in various industries, such as food, pharmaceutical, chemical, mineral, among others. Let’s explore what a vibrating sieve is for and how it works:

What is it for:

Sieving Materials: The main function of a vibrating sieve is to sieving solid materials, separating them according to their sizes or specific characteristics.

Particle Classification: It classifies solid particles into different fractions based on size, allowing the production of products with the desired particle size.

Impurity Removal: In industrial processes, the vibrating screen can be used to remove impurities, such as unwanted large pieces, from granulated products.

Preparation of Materials: In the food industry, for example, vibrating sieves are often used to prepare ingredients, separate powders or granulates, and ensure the quality of the final product.

How it works:

Basic Structure:

The vibrating sieve is composed of a structure that supports one or more screens or meshes. These screens are responsible for separating particles.

Vibrating Mechanism:

The sieve is equipped with a vibrating mechanism that generates oscillatory or linear movements in the screens. This vibratory movement is fundamental to the sieving process.

Material Feeding:

The material to be screened is fed into the vibrating screen, usually at the top of the machine.

Layer Sieving:

The vibrating movement causes the material to be distributed evenly over the screen. Smaller particles pass through the mesh spaces, while larger ones are retained.

Fraction Separator:

As the material moves over the vibrating screen, different fractions are separated and collected at different outlets. This allows classification by particle size.

Amplitude and Frequency Adjustment:

On many vibrating screens, it is possible to adjust the amplitude and frequency of vibrations, allowing the screening process to be adapted to different types of materials and classification requirements.

Disposal of Unwanted Products:

Unwanted particles or contaminants larger than the desired size are discarded into the corresponding outlet.

The vibrating screen is a versatile and effective equipment for screening solid materials in various industries. Its ability to classify materials efficiently makes it essential in many production and quality control processes. |

|

|

|

|

Brand: Biasinox, Fortress, MVL

Line for manufacturing soft chocolate sprinkles.

Approximate production capacity: 24 tons per month.*

*considering 8 hours of work per day.

Line composed of:

- Stainless steel jacketed pan with internal steam system.

With carbon steel st... |

|

|

|

Brand: MVL

Circular stainless steel vibrating screen with 2 stages.

Manufacturer: MVL.

Model: PRD115.

With carbon steel structure.... |

|

|

|

Brand: MVL

Stainless steel horizontal vibrating screen.

Manufacturer/brand: MVL.

Model: P.H 1500 X 600 1.D.

With perforated stainless steel plate with 0.9 mm and 0.6 mm openings.

It has feeding and discharge nozzles, and a drawer-type deck fixing sy... |

|

|

|

Brand: MVL

Components: Donar

Stainless steel vibrating sieve for continuous sieving.

The equipment has 4 outlets for sieved product per screen set level.

Equipment dimensions:

Possible manufacturer brand: MVL Donar vibrating machines.

Approximate length of the useful... |

|

|

|

Brand: Águia Inox

Vibrating filter sieve.

Manufacturer / brand: Águia Inox.

Model: FBO20.

Approximate capacity: 20,000 liters per hour.

Year: 2018.

Empty weight: 200 kg.

To filter the fine casein present in the whey from cheese processing, the whey p... |

|

|

|

Rotary sieve for separating materials.

Estimated production capacity: 100 tons per hour depending on the material.

It comes with a sieve and 2 conveyors for input and output of raw materials.

This industrial sieve is a robust and effective s... |

|

|

|

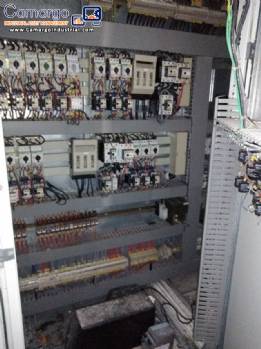

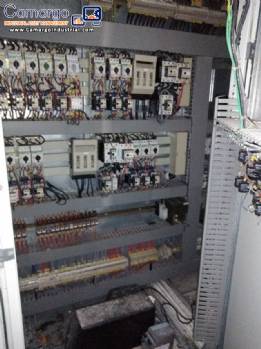

Flour transport system.

To transport flour from the silo to the scales.

With control panel, vibrating sieve and flour dispenser.... |

|

|

|

Brand: Dedini

Silos complete with structure / system for receiving, storing and transporting flour.

Year: 2003.

They were used in the food industry for the production of biscuits.

6 flour silos of 25 tons each.

5 silos of 165 m³ each.

1 sugar silo o... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Photos and images sent by email will be considered as ad authorization on our websites and marketing.

Camargo Industrial has no responsability for the data delivered by the advertiser, (Operation, technical, maintenance, warranties, technical delivery) and registration of the same data, exempting Camargo Industrial responsibilities on the veracity of the information described, civil and criminally.

The advertiser declares that the equipment is their property, settled without alienation, pending fiscal or judicial attachment.

Standard Work Safety of Machines and Equipment (NR12): 12.1.1. Camargo Industrial does not participate in the use phase construction, transport, assembly, installation, adjustment, operation, cleaning, maintenance, inspection, decommissioning and dismantling of machinery or equipment, any such liability of the seller attributes and / or buyer, relieving - any responsibility Camargo Industrial.

|

|

| |

|